Integrated Design Offshore———the hero behind the offshore wind power

2021/08/16 Source:ChinaOffshoreWind

In June 2021, the Vietnam Bac Lieu Phase III and Ca Mau Phase I offshore wind power projects, which applied the integrated design of iDO (integrated Design Offshore) offshore wind turbine support structure, completed the first hoisting of the project, with a total project capacity of 171MW.

From March 2018 to December 2020, several offshore wind power projects such as Guangdong Xuwen, Guangdong Shapa, Fujian Changle, Dafeng H8-2, Huaneng Guanyun, Dalian Zhuanghe and other offshore wind power projects have successively applied iDO integrated design methods. The total project capacity of this design method exceeds 1970MW.

What exactly is iDO?

To understand iDO, we must first start with the development situation of offshore wind power in my country and even the world.

In response to the contradiction between the split design of offshore wind turbine towers and foundations and the demand for cost reduction and efficiency enhancement of offshore wind power, Goldwind established an offshore wind power support structure integrated design project development team in 2017, and completed the offshore wind power in one year The development of integrated design methods for supporting structures and the establishment of digital platforms. In 2019, it officially launched the integrated design of offshore wind turbine support structure iDO (Goldwind Technology: "Sea, land and air" escort to win the future of high-quality wind power), which effectively reduces the tower bottom load of the wind turbine tower and improves the design of the support structure of offshore wind turbines Level, opening up new ideas for reducing the LCoE of offshore wind power.

Dr. Endi Zhai, Director of the National Wind Power Engineering Technology Research Center, Secretary-General of the Offshore Wind Power Branch of the China Ocean Engineering Consulting Association, and Chief Engineer of Goldwind Technology Group, said, “The'integrated design' originally originated from European offshore wind power. In recent years, offshore wind power has supported The structural integration design method has become one of the important methods to try to support structural cost reduction optimization at home and abroad. Goldwind completed the construction and development of the iDO digital platform as early as 2018, and built LCC clusters through the HPC-based local cloud platform , To achieve efficient and fast simulation calculation and design optimization, which is a technological first in the industry. It is worth mentioning that iDO was supported by the World Bank at the beginning of its development, and obtained the DNV-GL conformity statement in 2019. In the same year, it won the first prize of the Science and Technology Progress Award of the Chinese Renewable Energy Society. We believe that iDO will make greater contributions to the era of parity in offshore wind power."

Offshore wind power is the technical integration of marine engineering and wind power equipment. The vigorous development of offshore wind power will effectively promote the upgrade of wind power equipment R&D and manufacturing capabilities. Goldwind is willing to continue to rely on technological innovation to assist the overall smooth transition of offshore wind power to the parity stage and continue to promote The integrated development of my country's marine industry has realized the strategy of a maritime power.

From March 2018 to December 2020, several offshore wind power projects such as Guangdong Xuwen, Guangdong Shapa, Fujian Changle, Dafeng H8-2, Huaneng Guanyun, Dalian Zhuanghe and other offshore wind power projects have successively applied iDO integrated design methods. The total project capacity of this design method exceeds 1970MW.

What exactly is iDO?

To understand iDO, we must first start with the development situation of offshore wind power in my country and even the world.

The birth of iDO: Solving the contradiction between the rapid development of offshore wind power and the transition to parity

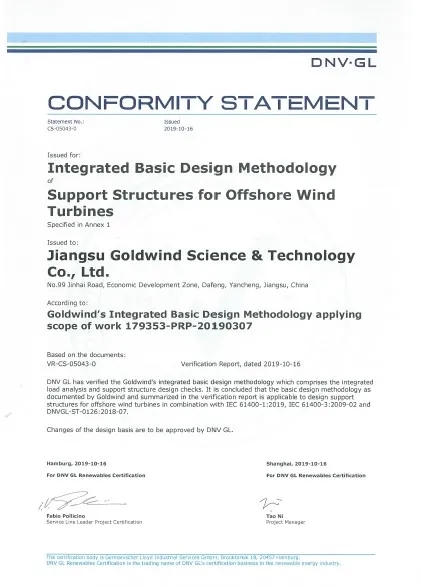

In the first half of 2021, the country's newly installed wind power installed capacity was 10.84GW, of which offshore wind power installed 2.15GW, a year-on-year increase of 102.5%. According to forecasts by authoritative organizations, China is about to give birth to another "world first": my country's cumulative offshore wind power installed capacity is expected to surpass the United Kingdom by the end of 2021 and become the world's largest offshore wind power market. The huge installed capacity of offshore wind power reflects the continuous improvement of my country's offshore wind power policy mechanism, the rapid development of the industry and the continuous progress of technology. As a participant, witness and promoter of China's offshore wind power industry, Goldwind is also working hard to contribute to the upcoming era of offshore wind parity pricing. Compared with onshore wind power, offshore wind power has a longer construction period, more difficult construction conditions, and more difficult construction; in general, the cost of offshore wind power is basically twice the cost of onshore wind power. At the same time, the cost composition of offshore wind power and onshore wind power is also very different. The construction and operation and maintenance costs of offshore wind power account for much higher than onshore, especially the procurement and installation of offshore support structures, which account for approximately the total cost of offshore wind power projects. About 30% of it. Therefore, reducing the cost of the supporting structure can significantly reduce the cost of offshore wind level-standardized per kilowatt-hour (LCoE), help offshore wind power to smoothly transition to the parity stage, and greatly improve the competitiveness of offshore wind power.Comparison chart of wind farm construction cost composition

In response to the contradiction between the split design of offshore wind turbine towers and foundations and the demand for cost reduction and efficiency enhancement of offshore wind power, Goldwind established an offshore wind power support structure integrated design project development team in 2017, and completed the offshore wind power in one year The development of integrated design methods for supporting structures and the establishment of digital platforms. In 2019, it officially launched the integrated design of offshore wind turbine support structure iDO (Goldwind Technology: "Sea, land and air" escort to win the future of high-quality wind power), which effectively reduces the tower bottom load of the wind turbine tower and improves the design of the support structure of offshore wind turbines Level, opening up new ideas for reducing the LCoE of offshore wind power.

Principle of iDO: Integrated design reduces redundancy

Taking the Vietnam Bac Lieu Phase III and Ca Mau Phase I offshore wind power projects as examples, if the traditional step-by-step iterative design method is adopted, the tower bottom is used as the interface, and the foundation and the tower are separated for separate step-by-step iterative design. All parties of the design institute search for the local optimal solution of the part they are responsible for, and will repeatedly consider the influence of waves and ocean currents, resulting in excessive design redundancy, which is not conducive to the optimization of the overall design. At the same time, the step-by-step iterative method often requires multiple iterations by multiple parties, and the design cycle is long. In the actual engineering design process, the Goldwind Technology team worked closely with the design team of South China Institute of Technology. By using the iDO integrated design method, the wind turbine tower and foundation were designed as a whole, taking full account of the coupling effects of wind, wave, and current loads. Through integrated modeling, integrated load calculation and integrated structure check, the conservativeness caused by repeated consideration of the load safety factors of different standard systems was avoided, and the global optimal design plan was found from the perspective of the overall support structure. In these two projects, through the use of the iDO integrated design method, the support structure of each wind turbine was reduced by about 11 tons (compared to the traditional step-by-step iterative method), which saved the owner over 10 million yuan in construction cost. This has been unanimously affirmed by the owner and the design institute; at the same time, the design delivery cycle of the project has also been greatly shortened.

The value of iDO: The load of the supporting structure can be reduced by more than 15%, and the design delivery time can be reduced by more than 30%

In many offshore projects such as Guangdong Xuwen, Guangdong Shapa, Fujian Changle, Dafeng H8-2, Huaneng Guanyun, Dalian Zhuanghe and other offshore projects that have widely used the iDO integrated design method of Goldwind Technology, the supporting structure load is generally effectively reduced by 15 % Above, the design delivery time is reduced by more than 30%.Dr. Endi Zhai, Director of the National Wind Power Engineering Technology Research Center, Secretary-General of the Offshore Wind Power Branch of the China Ocean Engineering Consulting Association, and Chief Engineer of Goldwind Technology Group, said, “The'integrated design' originally originated from European offshore wind power. In recent years, offshore wind power has supported The structural integration design method has become one of the important methods to try to support structural cost reduction optimization at home and abroad. Goldwind completed the construction and development of the iDO digital platform as early as 2018, and built LCC clusters through the HPC-based local cloud platform , To achieve efficient and fast simulation calculation and design optimization, which is a technological first in the industry. It is worth mentioning that iDO was supported by the World Bank at the beginning of its development, and obtained the DNV-GL conformity statement in 2019. In the same year, it won the first prize of the Science and Technology Progress Award of the Chinese Renewable Energy Society. We believe that iDO will make greater contributions to the era of parity in offshore wind power."

↑iDO obtains DNV-GL conformity statement

Offshore wind power is the technical integration of marine engineering and wind power equipment. The vigorous development of offshore wind power will effectively promote the upgrade of wind power equipment R&D and manufacturing capabilities. Goldwind is willing to continue to rely on technological innovation to assist the overall smooth transition of offshore wind power to the parity stage and continue to promote The integrated development of my country's marine industry has realized the strategy of a maritime power.

Image source: Goldwind Micro-platform